Cable entry hygienic

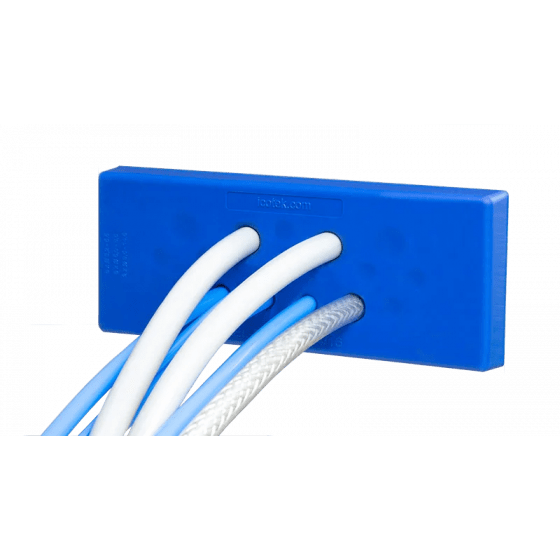

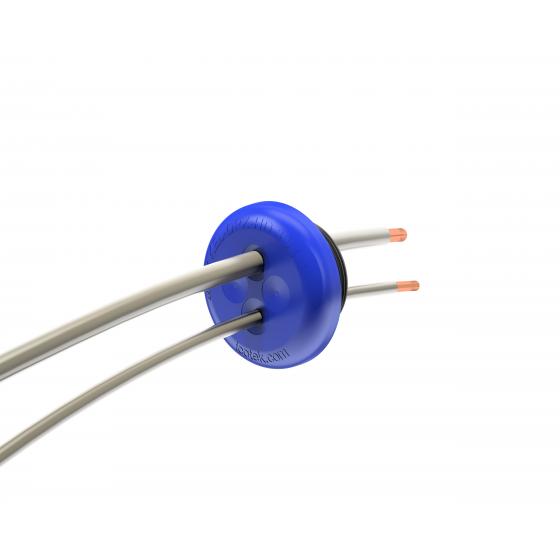

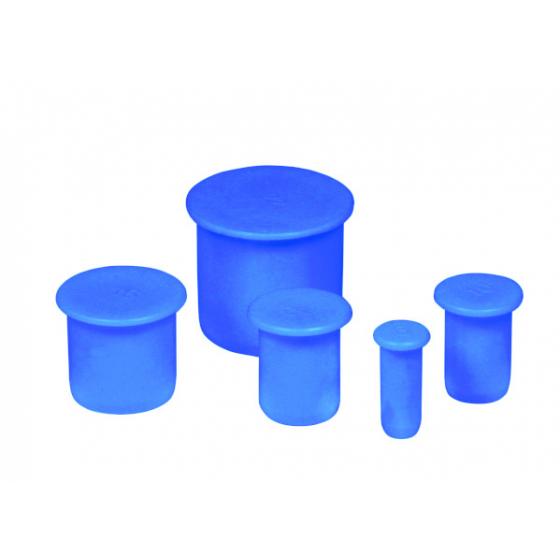

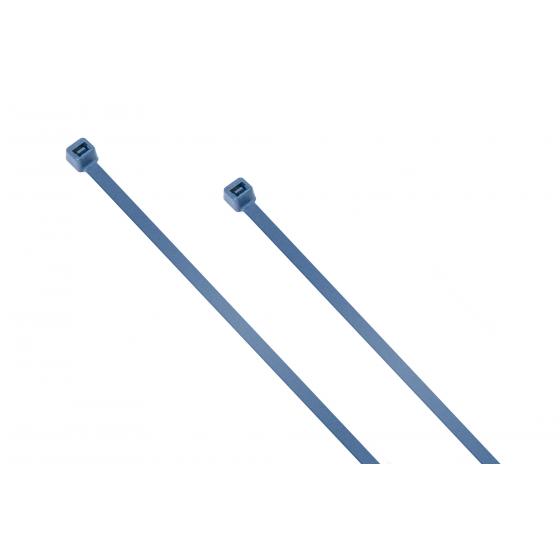

Pharmaceutical and food production companies, as well as animal feed and pet food manufacturers, need to meet hygienic standards. The cable entry plates with hygienic design are designed for use in such environments. The icotek KEL-DPU-HD and KEL-DPZ-HD are entry plates for use in zone 2 and 3 areas, also known as the splash and non-food areas. The ST-B-HD blind plugs are made to seal the openings in the entry plates when not in use. With the hygienic design cable ties, you ensure an orderly routing of cables for machines and equipment.

Read moreRead more

Usage of cable entry plates

The machines and equipment in production spaces are connected via various cables. As a producer and supplier of machines, you naturally want to neatly manage these cables. This looks tidy, is safer, and above all, more hygienic. CC Nederland is the official Dutch distributor of the German icotek and supplies cable entry systems in various types and sizes to the machine building industry. The icotek KEL-DPU-HD and KEL-DPZ-HD are available in round and rectangular variants.

Choose the size and openings you need for your specific situation.

Benefits

The cable entry plates comply with FDA standards, are designed according to EHEDG guidelines for hygienic design, and are Ecolab certified. The elastomer of the cable plate complies with the 1935/2004/EC regulation and the (EU) 10/2011 regulation.

Other key benefits include:

- Blue signal colour;

- Very flat design with a surface roughness of Ra 0.421 μm;

- Maintenance-free and easy assembly/cleaning;

- Cable diameter with (metric) openings from 3.2 to 22.2 mm;

- High cable density;

- More cost-effective than fully stainless steel systems and stainless steel cable glands;

- High protection degree IP66/IP68 through double membrane technology;

- High strain relief and stability/resistance to vibrations;

- Corrosion-resistant and high resistance to oils, lubricants, and mineral or aromatic products due to treated plastics.

Different zones in the food industry

As a machine builder for the food industry, you are probably familiar with the three zones for food safety. These three zones are: the ‘food’, ‘the splash’ and the ‘non-food area’. Each zone has specific requirements for the use of components such as cable entry systems.

Zone 1: Food area

These are the surfaces of machines that come into direct contact with food. This also includes parts that may indirectly contact the food, for example, when condensation occurs at warm temperatures. In practice, this means that everything directly above the food also falls within this ‘food zone’.

Product Advice: Zone 1 must comply with: EHEDG certification, adherence to EHEDG construction guidelines, and IP69K. Although it is unusual for cables to be used in this zone, the icotek products are unsuitable for this food zone.

Zone 2: Splash area

Zone 2 is the space where surfaces potentially come into contact with food through splashing or overflowing. Unlike zone 1, the food does not return to the regular production line and thus to the food products that eventually leave the production space.

Product Advice: The icotek products with hygienic design, KEL-DPU-HD & KEL-DPZ-HD, are suitable for zone-2 applications. The other icotek cable entry systems, KEL-ER-BL entry frames and KT-BL grommets, are officially unsuitable for this zone.

Zone 3: Non-food area

The non-food area includes all spaces and surfaces outside the aforementioned areas.

Product Advice: For these zones, both the icotek cable entry systems with blue design, as well as the cable entry plates with hygienic design, are suitable.